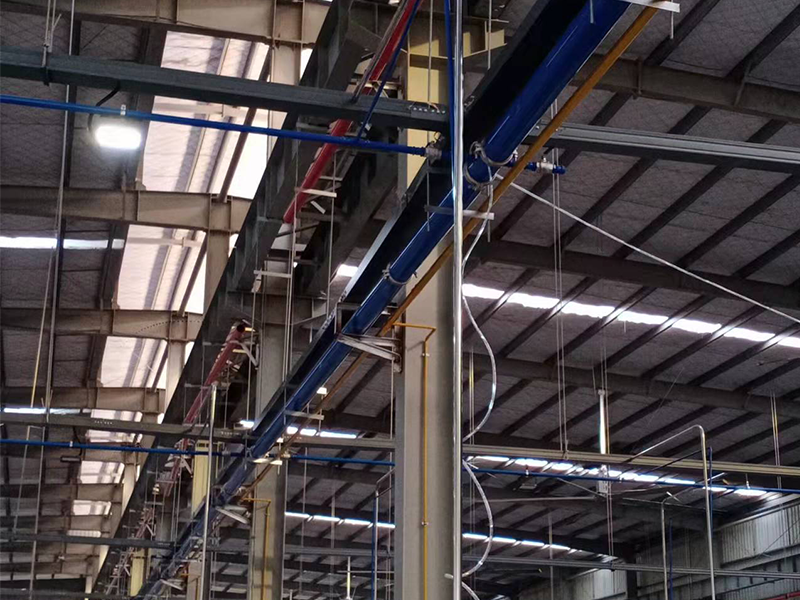

Our Pipe and Fittings stand as vital components in compressed air systems, engineered to deliver uncompromising performance under demanding conditions. Their precision-machined profiles ensure airtight connections across diverse pipe diameters, effectively minimizing pressure drops that can hinder system efficiency.

Crafted from high-grade carbon steel, these compressed air pipe fittings resist corrosion caused by moisture, oil residues, and contaminants often present in compressed air streams, thereby extending service life and reducing maintenance frequency. The modular design accommodates complex piping layouts, effortlessly handling elbow, tee, and cross connections to optimize airflow in industrial settings.

Whether integrated into automotive assembly lines, pharmaceutical cleanrooms, or manufacturing facilities, our press fittings maintain consistent pressure delivery to pneumatic tools and equipment. This reliability translates to uninterrupted production processes and lower operational costs. Each unit undergoes rigorous testing to meet industry standards, guaranteeing compatibility with both standard and high-pressure compressed air systems.